A Gravel Bike Built For Adventure

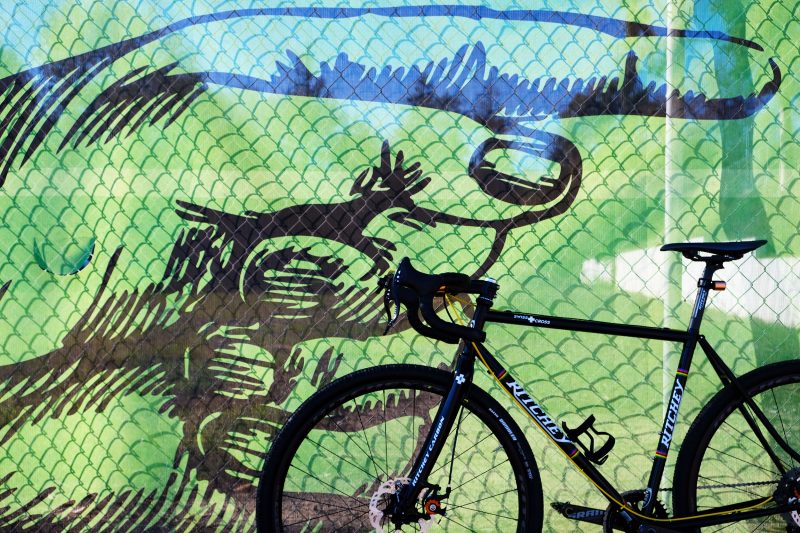

From start to finish, building the Ritchey Swiss Cross Disc was one of the most rewarding experiences. Budget aside, a gravel bike doesn’t carry a stereotype that forces a rider to reach beyond their comfort zone when building the right bike for their needs.

There is no question that a gravel bike can take many different forms; we’ve seen gravel grinders, all-road, touring, cross, and even mountain bikes converted for this use. The idea of riding dirt tracks and hard-packed trails on a road inspired frame constantly challenges our creativity. As a cycling community, we are simply wired to constantly push boundaries and find creative solutions to keep us occupied. With that said, we approached this semi-custom project with the goal of building a gravel bike — that’s dirt ready — to met three key needs: durability, craftsmanship, and simplicity.

Ritchey Swiss Cross Disc Frame

You don’t have to do much research to understand how closely a Ritchey Logic frame aligns with our three key needs. Steel has been around since the early days of cycling and shows no signs of disappearing. The famous saying, “steel is real” shouldn’t be taken lightly; when used correctly it’s still a mighty fine material for crafting the perfect bike. View Swiss Cross Disc Sizing

So why the Ritchey Swiss Cross Disc? Similar to aluminum and carbon, steel comes in so many varieties that even the avid cyclist can easily be fooled by what they are truly buying. With over 30 years of business experience Tom Ritchey has been producing high-level steel frames for both road and mountain use. Rather than giving in to newer materials he constantly pushes to further innovate steel as it pertains to bike building; this is evident in the Swiss Cross Disc.

This seemingly classic design incorporates heat treated, triple-butted Logic II tubing which also uses a sloped top tube for ease of shouldering — this can be beneficial when crossing a stream or rock garden. At 1960g for a 55cm frame, this design is significantly lighter than what you would expect from steel. The low weight and shared steel tubing creates a lively ride that only titanium can match.

We clearly remember pulling the Swiss Cross Disc out of the box thinking — there is no way that this is a steel frame — it felt that incredibly light. This was a pleasant surprise for the beginning stages of the project.The proprietary race-inspired steel is paired with a full-carbon fork, including the steerer; this helps to reduce the overall weight of the bike significantly. You won’t find a thru-axle on this frame set but you can’t have it all… or can you? The Ritchey Outback shown at Interbike 2016 looks to change this once and for all.

The head tube on the Swiss Cross Disc adds some character to this build. Although it looks like a classic touch, Tom designed this forged and machined head tube himself with integrated bearing cups. This is yet another feature that reduces the weight of the frame while increasing the durability. It’s also nice to see that Ritchey provided their WCS headset to make life easier.

The left seat stay on this frame lends itself well to building up a true gravel bike. It’s distinctive wave design leaves plenty of clearance for the disc brake setup. Our front-back 160mm Shimano center lock rotors look dialed and have plenty of room for shedding mud. Somehow this wave-shape design looks entirely natural and quite sexy if we’re being open with each other. Throw in full length cable housing stops and this frame gave us the option of cable or hydraulic brakes.

We mentioned in the beginning that our passion for bikes and design is what lead us to this project. With that noted, Ritchey’s engineering team added seemingly small details that don’t go unnoticed. For example, an aluminum c-clamp would work just fine for adjusting a seat post but it would unfavorably change the lines of the frame. Therefore the Swiss Cross Disc was built with an integrated seat tube clamp that looks incredibly clean. Plus it gives us a substantial reason to continue collecting multi-tools for riding.

Ritchey EVOMAX Bar and Paul Boxcar Stem

Coming from a mountain centric past, we have always been fond of big stems — you know, the metal thing that connect the fork to the bars. With craftsmanship being such an integral factor to our project, we connected with Paul Components to seek out some aircraft alloy. The 90mm +/- 15 Boxcar stem sure does look pretty in person.

Not only does it provide a secure mounting point for bars but it also demands a second and third look. It’s true boxed appearance is just what we wanted for gravel build; there is no lacking confidence when gripping down on the bars. Anodized in black, the Boxcar stem is unique in appearance with the intention of providing riders the best strength to weight ratio possible. Just read this brief note from the Paul Components team to see for yourself:

“This stem was designed from the ground up to be stiff, strong and pretty darn light too. We went through several design iterations and believe we’ve reached the best combination of these three principles. Extensive real world and machine testing and proven this to be one strong stem. With respect to torsion, the rounded box shape is some 25% stiffer than the competition. As for strength, we ran it through 1,000,000 cycles of above normal use stress without a single problem.”

“By allowing the function and material properties dictate the shape of the product, we have come up with another one of our often complimented and purposeful designs. Yes, it looks a little different, but with us there is always one good reason for this: to make it work as awesome as possible.”

Seeking for maximum stability, we paired the Boxcar stem with the 46cm Ritchey WCS EVOMAX bars. All cyclists can undoubtedly share the benefits of receiving a proper bike fit; benefits from comfort to long-term health are just a few to name. But a capable gravel bike shouldn’t be viewed as a traditional road bike setup. It’s a culmination of years and years of road bike abuse and dirt-filled desires joining together to form an effective solution.

Bar width is yes another distinctive component specification when riding on the dirt, so please don’t skimp on this feature. Knowing enough about the current offering we couldn’t go wrong with the 270g flared 7075 alloy for the unpredictable rides ahead of us. We’re not looking to win any medals here but a participation trophy would be nice. The 12 degree flare feels adequate for most rides and offers forearm clearance that would otherwise be nonexistent with a traditional drop. If you plan on commuting with a gravel build this bar is nearly perfect. If you see the potential for some bike packing or gravel grinding go with even more flare for comfort and safety.

Gevenalle GX2 Shifters

The idea behind this gravel bike project was to build a machine that’s capable of tackling messy conditions that most road bikes wouldn’t touch. Oh yeah, it needs to bombproof, hand-crafted and overly simple to ensure that it’s equipped for long adventures; look no further than Gevenalle: “there are a host of excellent road parts available but when the road ends and the ride gets dirty there is only one set designed specifically for the task.” — Gevenalle

Why Gevenalle? When planning our gravel build we started with the concept that our riding environment will always be challenging. Shifters that are serviceable on the trail are also an invaluable feature for multi-day trips. We also wanted to outfit the bike with indexed shifting that was simple to use during the most grueling conditions. The Gevenalle GX2’s are the unicorn of the drop bar world; they are adaptable to nearly any setup you can imagine. Short-pull, long-pull, v-brake or disc, you name it these shifters won’t fail on you.

We chose to pair the Gevenalle GX2 shifters with a Shimano XT 1×11 rear derailleur and 11-42 cassette — the riding options have been limitless within reason so far. The drop bar integrated shifter for mountain components feels quite solid but not intrusive to your space on the hubs. And if you need to use a greater drop flare with a front rack or bag, these shifters provide adequate room. Furthermore, if we happen to smash the rear derailleur on a rock or tree, we can adjust the shifters to friction mode and ride on. From mud, sand and rain to ice and rocks, the Gevenalle GX2’s add a level of confidence that we need out on a ride.

Paul Components Klamper Brakes

The frame and unique Gevenalle shifters set the tone for this build. It didn’t take long for us to uncover an unexpected attraction to Paul Components and everything that they stand for. Although you can’t beat the performance of hydraulic disc brakes, they didn’t meet our need for complete simplicity. Out of the box the Paul Klamper Brakes perform better than any mechanical brake we have used. They engage and disengage with feeling while remaining smooth. Shit happens on the trail and mechanical disc brakes are undeniably easier to adjust and service when the unexpected happens, which is why we chose to install Klamper’s from Paul Components.

Not only were they refreshingly simple to install, their radical design and anodized shine deserve extra attention. A dedicated in-house engineering team has designed the Clapper brakes to excel for gravel riding. The entire system feels so well made and really complemented our build well. They also seem to be the root of many trail conversations so far — fellow riders can’t get enough of them! With only a few rides under our belt so far we are just ‘braking’ them in and boy are they feeling solid.

The team at Paul has put some serious man hours behind their creation; we urge you to read about them from their in-house perspective:

“When we set out to build this brake, nearly three years ago, we started with a clean slate. Then we tried all manner of whacky ideas but eventually wound our way back to the tried and true ball bearing in a ramp system.

From there we concentrated on the details. We made the balls bigger for smoothness and increased pad travel. We hardened the steel where the balls contact the ramps. We used three hardened steel pins to locate the pad actuator. Instead of a plastic thrust washer we used a flat needle roller thrust bearing.

Then we moved onto the caliper body. This took countless drawing revisions and probably 20 prototypes. We added “fangs” to the inner backing plate for stiffness, and beefed up the outer caliper body where needed.The pad adjusters went through a similar process. We wanted easy adjustability but staying power. For that we designed detents into the circumference, located with spring ball plungers.We believe this is the best mechanical caliper ever made for a bicycle.

It’s available in long pull and short pull, just change the actuating arm, both of which are available separately.We decided not to make rotors. That’s a manufacturing process we do not do, and they are readily available. The pads are Kool Stop sintered metallic. As always, allow a couple short rides to bed in the pads.”

Ritchey WCS Zeta Disc

When deciding to build a semi-custom gravel bike we had a feeling that we might be paralyzed by all of the component choices available to us; we were right. Given that the Swiss Cross Disc still features both a front and rear quick release, it was a unanimous vote to go with the Ritchey WCS Zeta Disc wheel-set; they have been engineered to pair seamlessly with our frame choice.

Remembering our three key needs, the Zeta Disc wheels are super durable on the dirt, hand built by the Ritchey staff, and simple to install — they have been kind to us when seating tires in a pinch. Though these hoops were built for the cross course, their weight of 1560g makes them a suitable choice for trail use. From shedding mud to deflecting rocks we didn’t see a need for carbon just yet.

The bike has been spec’d for a rider that only weighs a buck fifty-five so it’s hard to tell if their stiffness is acceptable for all potential riders. They do in fact feel superb on the hardback and even more snappy on the pavement. In all honesty, Ritchey chose build characteristics such as a forged, machined and staggered hub flange, disc-only OCR rim extrusion, and forged and machined phantom disc hubs to cater to the gravel crowd.

As a functional unit the Ritchey frame and wheel combo has proved to be a smart choice. We were shocked to experience how solid a somewhat classic design can be. It’s no thru-axle feel but it’s certainly a close second in terms of tracking and stiffness. Although the Swiss Cross Disc in tested with a maximum tire clearance of 38c we proved to mount 40c with room to spare — maybe even enough for fenders.

As expected this wider tire profile forces the wheels to flex a bit more than usual but not enough to raise concern. After all, this bike is meant to shred terrain that isn’t as predictable as the road so a little extra flex is welcomed. Additionally, the Zeta Disc wheels use an oversized cartridge bearing hub that performs far beyond its price point. This design has been used on Ritchey bikes far longer than I have been riding a road, gravel or cross bike and have some serious testing behind them. Again, we will take peace-of-mind over incredible weight saving or brand new tech any day — especially for a gravel bike.

Final Thoughts

Building a gravel bike has been a truly rewarding experience for us at Gearminded. As design thinkers we often find ourselves toying with bikes while looking for ways to build something different — this is a prime example. Carbon, steel and aluminum are all worthy materials for building up a fun yet capable rig and we successfully integrated all of these into our project. Aside from being dirt ready we wanted this bike to speak to the heart of the cycling community. By selecting parts that have an in-house tested durability, simple design and transparent craftsmanship we think our gravel build epitomizes the unity of blood, sweat and gears.

Complete Ritchey Swiss Cross Disc Build Spec

Frame: Ritchey Swiss Cross Disc

Heat treated, triple-butted Ritchey Logic II™ CrMo steel tubing throughout

Ritchey WCS Carbon disc cross fork, painted to match

Front: 140/160mm rotor compatible; Rear: 160mm rotor compatibility

Ritchey socket dropouts

135mm rear spacing

Room for tires up to 40c tires

WCS headset included

Weight: 1960g / 4.32 lbs (55cm, frame only)

Stem: Paul Components Boxcar 90mm +/- 15

Bars: Ritchey WCS EVOMAX 46cm

Triple butted 7075 alloy

Drop/Reach: 120/73mm

12 degree drop flare

4.7 degree sweep, 0 degree flare

Finish: Blatte or Wet Black (Intl only)

270g (42cm)

Shifters: Gevenalle GX2

Dyna-sys double, triple or single chainring compatible; short and long pull brakes

Bar tape: Brooks Cambium

Brakes: Paul Components Klamper

6061 Aluminum, Heat Treated Steel

211g

Anodized

Short Pull

Kool Stop Disc Brake Pads

Wheels: Ritchey WCS Zeta Disc

New forged and machined phantom disc hubs

Disc-specific, tubeless Zeta II OCR™ rims are light, stiff and wide

Forged, machined and staggered hub flange increases spoke bracing angle and builds a stronger, lighter wheel

Centerlock compatible

1,560 grams (735g front, 825g rear)

Rotors: Shimano XT RT81 Centerlock 160mm

Tires: Maxis Rambler 700x40c

Seatpost: Ritchey WCS LINK FLEXLOGIC Carbon

400mm

27.2 (181g)

Crankset: Sram Force 1x BB30 42T

Rear Derailleur: Shimano XT 1×11

Chain: Shimano XT

This is almost the exact build I envision for my next cross bike. I love the move toward durability and simplicity as well as having a bike for both gravel and cross racing.

I have a couple of more cyclocross oriented questions. I’m curious what the weight of the complete build ended up? Most modern steel CX and gravel bikes are coming with through axles, do you guys feel this is gimmick or is Ritchey behind the times and missing the boat on better handling?

Thanks

Hi Aaron,

Thank you for the question! Thru-axles undoubtedly provide greater strength, durability, and stiffness over QR. The Swiss Cross Disc has proved itself time and time again as a reliable bike for cross and gravel use. With that said, Ritchey announced the Outback — a gravel specific application that does use thru-axles, front and rear. On rough terrain and at higher speeds, you are correct, the handling will be more capable with the TA system. It looks like the Outback will have a slightly lower BB and slack head tube than the Swiss Cross. Still waiting on the release and availability. Let us know if you need more info! I will send over the final weight asap — the bike has been out in dirt since it’s completion. Too much fun.

Any update on the weight?

I’ve got one built with Sram Force 1×11, mech disc, and those zeta wheels floating at 20.50lbs.

Also, do yourself a favor and toss that seatpost… I hate to say it’s garbage. It’ll move on you if you hit a big bump or a bad remount.

Hi Blake,

We are just over 21lbs, however, we recently mounted these bad boys on there:

http://www.somafab.com/archives/product/cazadero-tires-700c650b-x-42mm

We haven’t had any issues with the post but we will definitely be cautious. I will be snapping some new photos with the gum-wall tires for the post — they fit!!

Holy cow… Cazadero’s fit? That’s awesome.

I’m running 38 Ramblers right now which offer great mud clearance. But I’ve always wanted Cazaderos… Might have to go with those after I wear out the Ramblers (but man, those 38’s are super fast on the road…).

Thank you for this article. I’m in the process of building mine now. Question, what size cassette did you go with for this build?

You are welcome and thank you for the message,

We went with the XT 11-40T on this one. It’s been great so far, and the wheels are plenty stiff to handle it.

If you need assistance on the build, feel free to send questions our way.

Thank you!

A follow-up post would be great — would love to see it with the 650Bs. Cheers! 🙂

Hey, which disc brake adapter did you use on the front brake? Been trying to find a 140mm to 160mm front post to post adapter without success. I’m assuming you used another adapter that did the trick. Thank you in advance for your response!

Hi Vernon,

Thanks for your question. I’m almost positive that we ordered the adapter from Paul Components in Chico, CA when we ordered the Klamper brakes. We can reach out to Ritchey for you if you can’t find what you need.

Let us know.